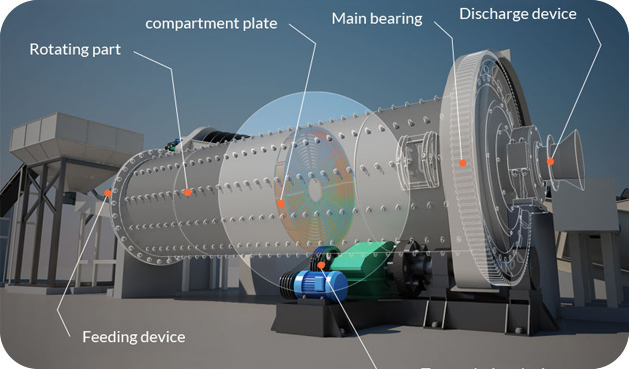

Working Principle

The raw coal enters the feeding device of the mill from the feeder equipment, and the hot air having a temperature of about 300 °C also enters the feeding device through the air inlet pipe. A special lifting plate is arranged in the drying chamber to raise the raw coal so that the raw coal is subjected to intense heat exchange here to be dried. The dried coal block enters the grinding chamber through a double-layer compartment plate with a lifting plate, and the grinding chamber is provided with steel balls. The coal block is pulverized and ground into pulverized coal in the chamber. At the same time that the coal block is pulverized, the pulverized coal powder and gas are taken out of the mill together by a special draft fan through the discharge device of the mill. The coarser particles are returned to the powder through the return screw of the discharge device and ground again in the grinding chamber.

Contact Us for Video Tour of the Factory