Brief Introduction

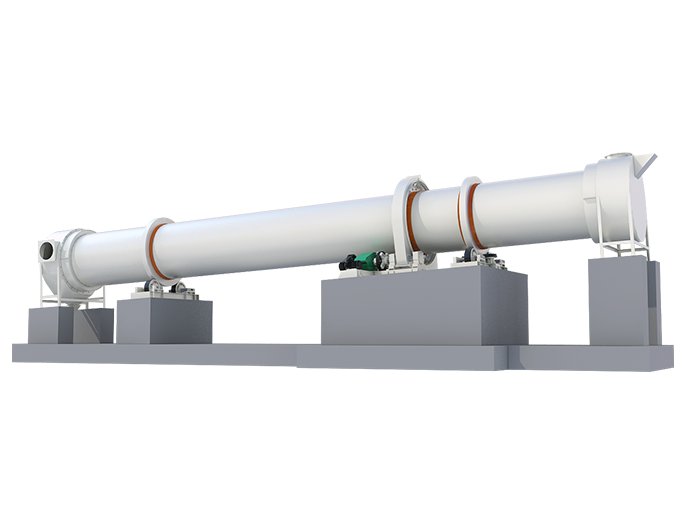

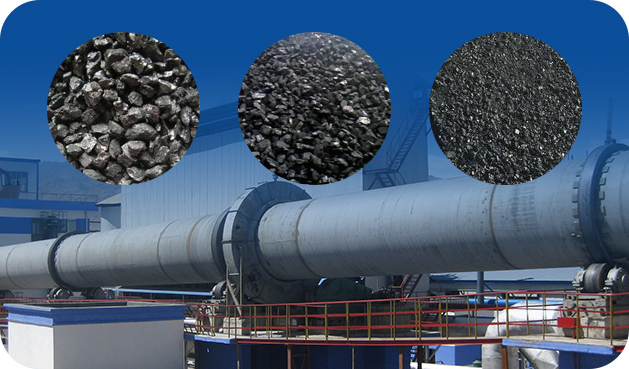

The lignite dryer is mainly used for drying lignite and the like. Rotary lignite dryer, under the condition of ensuring the quality of dried lignite, adopts a low-temperature four-stage drying process to evaporate lignite water to less than 13% water as fuel coal, which has good economic, social and environmental benefits.

The first-stage drying zone removes most of the water at a high temperature of 400 °C in a high-humidity state, ensuring that the chemical composition of the lignite does not change and is not easy to burn; the secondary drying zone has a room temperature of 300 ° C, and the water removal by medium-temperature strong wind to ensure that lignite is not coked; the indoor temperature of the third-stage drying zone is 120°C-210°C, and the crushing device in the drum is used to repeatedly impact and break up the material and dry; The four-stage drying zone is a high exhaust zone, and the room temperature is 60 ° C - 80 ° C, and the low-temperature hot air flow which is under negative pressure by the air intake system excludes water.