Brief Introduction

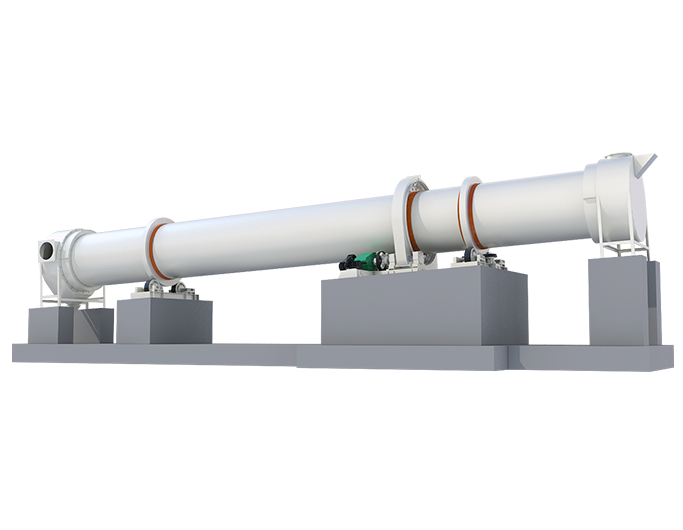

Slag processing and utilization requires a slag dryer (direct heat transfer drum dryer and indirect heat transfer drum dryer). Slag is also a major industrial waste produced in steel making operations. It can be made into cement, glass, and brick. It can also be used to make agricultural fertilizer or extract useful materials.

The slag dryer equipment has strong adaptability to materials and can dry various materials. Users can choose the machine according to their own needs.