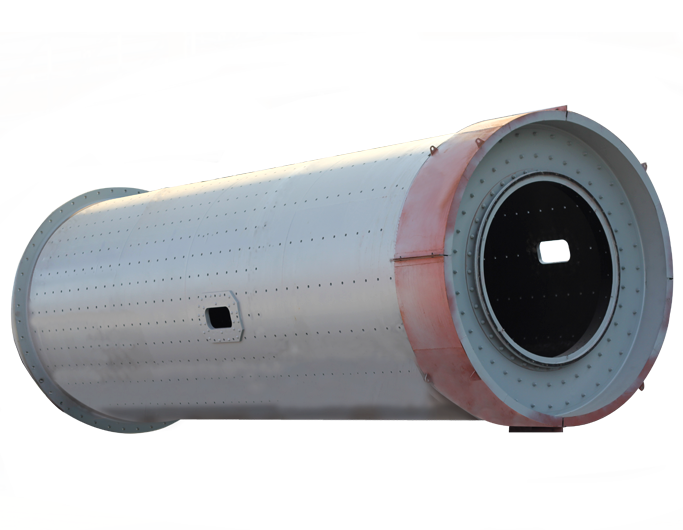

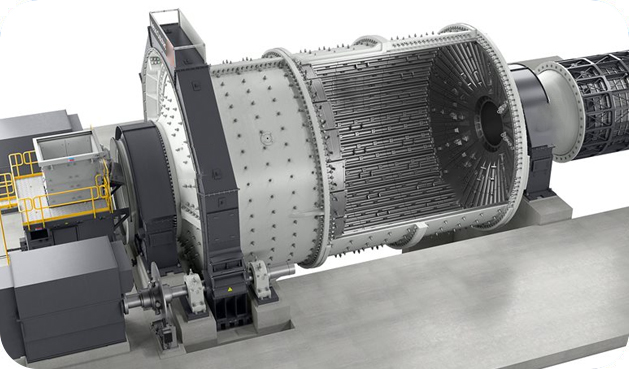

Brief Introduction

The cement mill is developed by our company (Henan Fote Heavy Machinery Co., Ltd.,) on the basis of traditional mills. It not only gets rid of the defects of traditional mills but also adds new technologies and performance. The cement grinding equipment can be produced either in a dry process or in a wet process, and can also be operated simultaneously by grinding and drying. The cement grinding equipment produced by our company is characterized by excellent quality and excellent craftsmanship. It has the characteristics of strong adaptability to materials, continuous production, large crushing ratio, and easy fine-speed grinding.