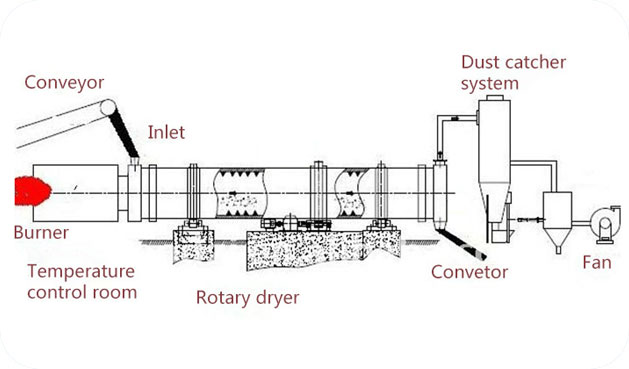

Brief Introduction

The cooler is one of the important machines in the rotary kiln system, is widely used in metallurgy, building materials, chemical, cement, construction, refractory, and other industries. The function of the equipment is to fully exchange heat between the clinker (1000-1200 ° C) from the rotary kiln through the barrel rotating material and air to cool the material below 200 °C. At the same time, it improves the quality and wearability of the clinker, and the air after cooling the material is all put into the kiln, and the secondary circulating air is used to improve the thermal efficiency of the kiln. The cooler has the characteristics of simple structure, high operation rate, and convenient operation and maintenance.