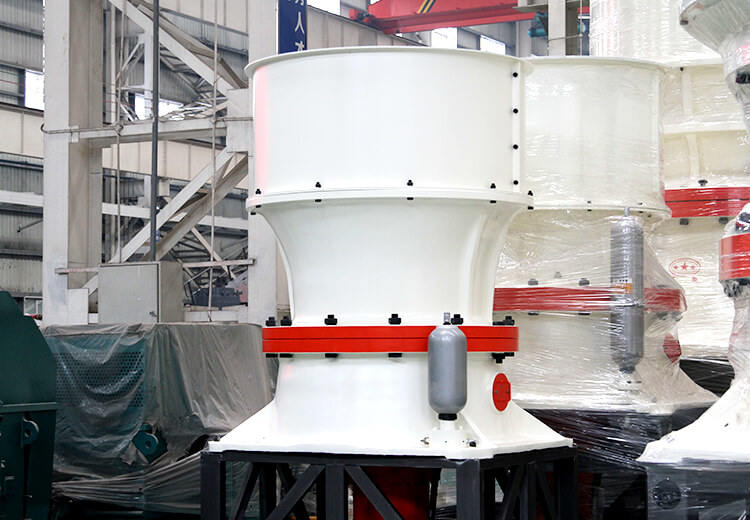

Single-cylinder Hydraulic Cone Crusher

Capacity 36-2020t/h

Feeding size 50-560mm

Applied material: barite, marble, calcite, kaoline, coal, gypsum, concrete.

Email us: sales@sinoftm.com

Free InquiryBrief In Single-cylinder Hydraulic Cone Crusher

The single-cylinder hydraulic cone crusher is widely used in metallurgy, construction, hydropower, transportation, chemical industry, building materials industry. It is suitable for crushing various ores and rocks with hard and medium hardness (intermediate, fine and ultrafine crushing process), such as river pebble, granite, basalt, iron ore, limestone, Quartz stone, diabase, iron ore, gold ore, copper ore, etc.

The hydraulic cone crusher adopts the unique crushing cavity shape and the laminating crushing principle to produce the crushing effect between the particles, so that the proportion of the cube in the finished product is obviously increased, the needle-like stones are reduced, and the particle size is more uniform. Therefore, it is highly recognized and favored by users in the industry, especially by metal mines and construction sandstone processing plants, and has become one of the hot sale devices in the industry.

Advantages

1.It adapts to a variety of discharge particle size requirements with a variety of cavity types;

2.The rolling wall does not need filler, and the replacement is quick and convenient;

3.The fully automatic control system of PLC+ touch screen ensures the safe operation of the equipment;

4.The double-insurance controlled hydraulic and lubrication system ensures overload protection and good bearing lubrication.

Technical Data

Moved Permanently

The document has moved here.

Apache Server at c.kssbchina.com Port 80

Service Guarantee

Round-the-clock tech support

- Offer customized solutions: Customized the economical and reasonable solutions according to the actual needs of customers.

- Installation and maintenance: Provide installation and the tracking service for the customer, free technical advice and guidance.

- Life Cycle Services: Perfect customer data, the lifelong service for customers, solve customer's worries in time.

Get Latest Price

We are here to help