Brief Introduction

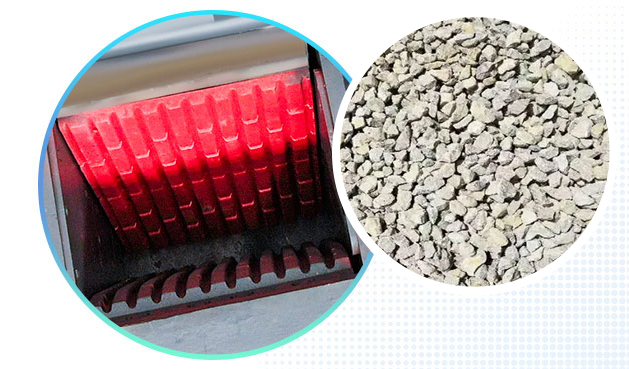

Limestone crusher is used for primary, secondary and fine crushing of limestones. After being crushed, limestone with different particle size can be used in cement plant, road, construction, chemical, garden, etc.

Limestone crusher is used for primary, secondary and fine crushing of limestones. After being crushed, limestone with different particle size can be used in cement plant, road, construction, chemical, garden, etc.

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw approaches the fixed jaw, and at the same time, the material is crushed to achieve the purpose of crushing; when the movable jaw descends, the angle between the toggle and the movable jaw becomes smaller. Under the role of pull rod and the spring, the movable jaw leaves the fixed jaw, the crushed materials are discharged from the lower mouth of the crushing cavity. With the continuous rotation of motor and the periodic motion of movable jaw, realizing mass production.

Welded frame structure, firm and reliable: The high-quality steel plate welded frame avoids casting defects, more stable and reliable.

01Reliable quality of the movable jaw: It is made of high wear-resistant gear plates, which has high durability and high performance. The movable jaw assembly is made of high-quality cast steel, more firm and reliable.

02Easy discharge adjustment: The new automatic control system realizes one-button adjustment, reliable and easy to maintain.

03High efficiency and energy saving: The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output. Its crushing ratio is large and the product size is uniform.

04

Our Limestone Crusher has been exported to over 160 countries, such as, Pakistan, Egypt, Indonesia, Malaysia, Ethiopia, Nigeria, South Africa, etc. Furthermore, we provide 100% factory price and maximum discount for you. Additionally, if you are new in this industry, we will provide professional suggestions and solutions for you.Get Quote

Nearly 40 years of production experience, well welcomed by customers from 90+ countries.

Expert design as your order and requirement, with all-around solutions to your problems.

Reasonable plan for grinding procedure and scientific production to help you to gain more profits.

Regular inspection and return visit, and solve your after-sale problems in time.

The document has moved here.

Henan Fote Heavy Machinery Co., Ltd., has been in existence for more than 40 years since its establishment. It has four production bases in China and its products are sold to more than 160 countries around the world, including South Africa, Tanzania, Nigeria, Botswana, Uganda, United Arab Emirates, Ghana, Sierra Leone, India, Indonesia, Singapore, Australia, Sri Lanka, Vietnam, Bangladesh, etc.

If your machine fails, production at the entire plant will be at risk. To avoid such losses, you can get critical replacement parts of the machine whenever you need it.

Our products support global logistics network distribution, ensuring that FTM brand spare parts or consumables are available when you need it.

Our fixed-model machines and consumables are available from stock to ensure customers get the machines they need in time.