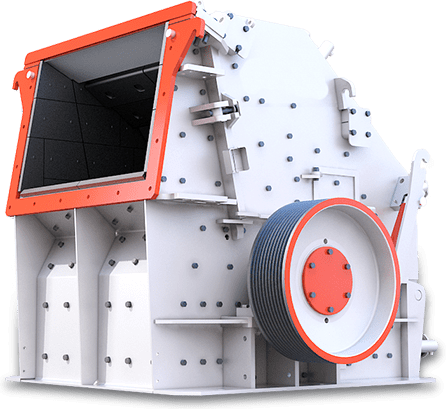

Impact Crusher

Impact crusher is used for secondary and fine crushing of stone and ores which compressive strength is not

more than 350MPa, widely used in railway, highway, energy, cement, chemical, construction and other

industries. The finished product is cubic, free of tension and cracks.

-

Production Capacity

30-800t/h

-

Input Size

≤800mm

-

Output Size

≤40mm

Processing Materials of Impact Crusher

It is widely used for secondary and fine (second and third stage) crushing of granite, river stone,

quarry stone, rock, boulder, gravel, aggregate, basalt, limestone, gold ore, iron ore, chrome ore, etc.

Adjustable final size meeting different needs. Following is common final output size.

Working Principle of Impact Crusher

Driven by the motor, the rotor rotates at a high speed. When the material enters the impact area of the

blower, it hits against with the blower, and then is thrown to the counterattack device to be crushed again,

and then the materials bounce back to the hammer action area to be crushed again. This process is repeated.

The material enters the first, second, and third counterattack chamber from large to small, and is

repeatedly crushed until the material is crushed to the required particle size and discharged from the

discharge port.

Advantages of Impact Crusher

![undefined]()

High efficiency and energy saving

Large feed inlet, high crushing cavity, high hardness of processed materials and less stone powder.

Qualified particle shape

The gap between the counterattack plate and the hammer can be easily adjusted, effectively controlling the

output size and the particle shape is good.

Optimized structure

Compact structure, strong rigidity, rotor with large moment of inertia.

High comprehensive benefit

High chrome plate hammer, impact resistance, abrasion resistance, high impact force.

Hot Issues of Impact Crusher

Hot Sale Models of Impact Crusher

PF1007, PF1010, small impact crusher, small power consumption, low costs.

PF1210, PF1214, PF1315, large production capacity and high efficiency.

Hot Sale Production Capacity of Impact Crusher

30-70t/h, 50-90t/h, etc, usually for small production scale, with low costs.

70-100t/h, 100-150t/h, 250-300t/h, etc, usually for medium and large production scale.

Related Projects of Impact Crusher

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New

Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

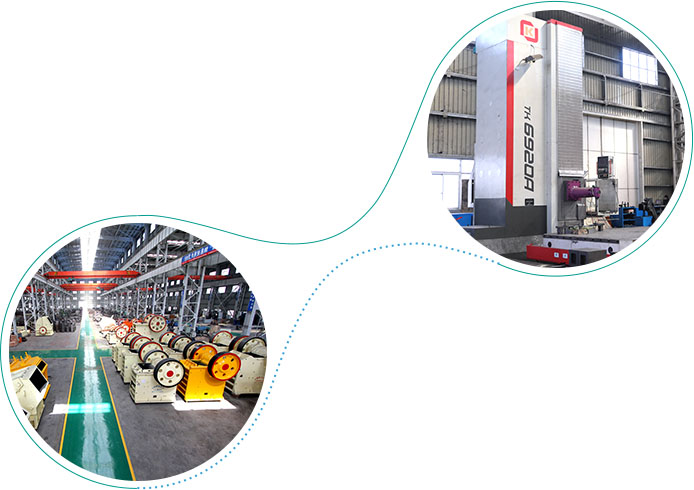

Company Strength

As leading manufacturer and supplier in China, we have four large sized modern workshops, more than 500000

square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every

product and every customer.

One-stop Solution

We provide full and professional service system, including customized solution, fast delivery, spare

parts, product warranty, product installation, etc.

Production Strength

with over 200 kinds of small, medium and large heavy processing equipment, such as vertical

lathe,edge planer, large boring machine, bending roll, etc.

![]()