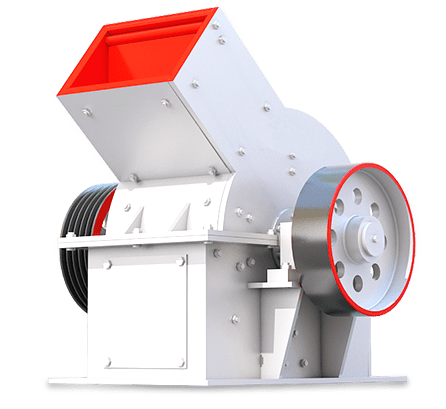

Hammer Crusher

Hammer crusher is suitable for crushing various medium hardness and brittle materials, with large crushing

ratio, high production efficiency, complete equipment models, low costs and other advantages, well received

by customers.

-

Product

10-500t/h

-

Input Size

≤750mm

-

Output Size

≤40mm

Processing Materials of Hammer Crusher

It is widely used for primary secondary fine crushing of granite, river stone, quarry stone, rock,

boulder, gravel, aggregate, basalt, limestone, gold ore, iron ore, chrome ore, etc. Adjustable final

size meeting different needs. Following is common final output size.

Working Principle of Hammer Crusher

When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material

enters the crusher cavity evenly. The high-speed rotating hammer impacts the material, making the stones

crushed. At the same time, the gravity of the material causes the material from the high-speed rotating

hammer head rushes to the baffle and the screen bar in the frame, and the material larger than the screen

hole size is blocked on the screen plate and continues to be crushed by the hammer until it is crushed to

the required discharge size and finally discharged out of the machine through the screen plate.

Advantages of Hammer Crusher

Wide application

Hammer crusher is especially suitable for crushing limestone and medium hardness stones with compressive

strength less than 200Mpa.

Reduce costs, low energy consumption

Need for second-stage crushing and shaping process, which can reduce the cost by about 40%, low energy

consumption and low investment.

High efficiency

Modular design, by changing the cavity type, the conversion of coarse, medium and fine crushing can be

realized, improving production efficiency

Long service life

High quality spare parts, easy maintenance, long lifetime.

Hot Issues of Hammer Crusher

Hot Sale Models of Hammer Crusher

PCΦ400×300, PCΦ600×400, small hammer crusher, small power consumption, low costs.

PCΦ1000×800, PCΦ1000×1000, large production capacity and high efficiency.

Hot Sale Production Capacity of Jaw Crusher

10-20t/h, 20-30t/h, 30-50t/h, etc, usually for small production scale, with low costs.

60-100t/h, 100-150t/h, 250-300t/h, etc, usually for medium and large production scale.

Related Projects of Hammer Crusher

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New

Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

Company Strength

As leading manufacturer and supplier in China, we have four large sized modern workshops, more than 500000

square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every

product and every customer.

One-stop Solution

We provide full and professional service system, including customized solution, fast delivery, spare

parts, product warranty, product installation, etc.

Production Strength

with over 200 kinds of small, medium and large heavy processing equipment, such as vertical

lathe,edge planer, large boring machine, bending roll, etc.