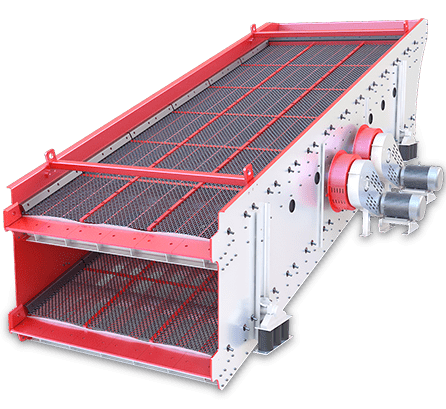

Vibrating Screen

Vibrating screen does circular movement in work, and it is a new high efficiency vibrating screen machine

with multiple layers. It is used for minerals particle size grading, necessary in mining, quarry and

construction industries.

-

Production Capacity

10-700m³/h

-

Input Size

≤200mm

-

Output Size

≤40mm

Processing Materials of Vibrating Screen

It is widely used for screening of granite, river stone, quarry stone, rock, boulder, gravel, aggregate,

basalt, limestone, gold ore, iron ore, chrome ore, etc. Adjustable final size meeting different needs.

Following is common final output size.

Working Principle of Vibrating Screen

The vibrating screen is mainly composed of a screen box, a vibration exciter, a suspension (or support)

device and a motor. The motor drives the main shaft of the exciter to rotate through the V-belt, and the

screen box is vibrated due to the centrifugal inertia force of the unbalanced weight on the exciter. By

changing the eccentric shaft of the exciter, different amplitudes can be obtained.

Advantages of Vibrating Screen

![1]()

High screening efficiency

Due to the strong vibration of the screen box, the problems of material blocking the screen holes is reduced,

so that the screen has a higher screening efficiency and productivity.

Simple structure, easy operate

The structure is simple and the screen surface is easy to disassemble and replace.

Long service life

A small amount of wearable parts are made of super hard and wear-resistant materials, which is especially

suitable for easy replacement of accessories.

Hot Issues of Vibrating Screen

Hot Sale Models of Vibrating Screen

2YK1230, 3YK1230, 2YK1237, suitable for small prodution scale.

3YK1854, 4YK1854, 2YK2160, suitable for medium and large production scale.

Hot Sale Production Capacity of Vibrating Screen

10-20m³/h, 20-50m³/h, etc, usually for small production scale, with low costs.

60-100m³/h, 100-150m³/h, 250-300m³/h, etc, usually for medium and large production scale.

Related Projects of Vibrating Screen

Our products have been exported to over 90 countries, such as Philippine, Pakistan, Vietnam, Papua New

Guinea, Feiji, Tanzania, Ghana, Cameroon, Kenya, South Africa, Nigeria, Somalia, etc.

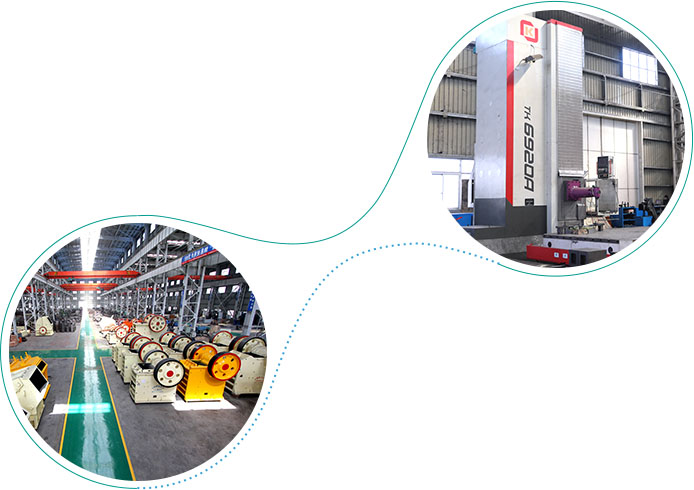

Company Strength

As leading manufacturer and supplier in China, we have four large sized modern workshops, more than 500000

square meters, reliable and trustworthy. We are dedicated to be responsible for every procedure, every

product and every customer.

One-stop Solution

We provide full and professional service system, including customized solution, fast delivery, spare

parts, product warranty, product installation, etc.

Production Strength

with over 200 kinds of small, medium and large heavy processing equipment, such as vertical

lathe,edge planer, large boring machine, bending roll, etc.

![]()