NEWS

What Are The Criteria for Choosing A Briquette Machine

By: Fote MachineryJanuary 11th,2021

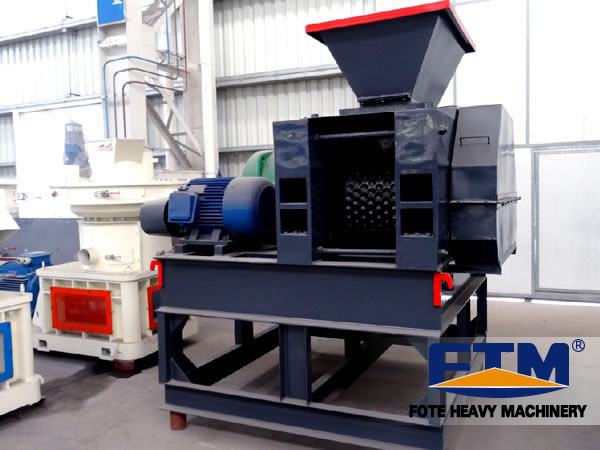

The briquette machine is specially designed and manufactured for the special processing of charcoal, coal powder, coke, coke powder and mineral powder. Many places are customized according to the actual situation reflected by users. The briquette machine can easily process charcoal into a spherical shape, which is convenient for enterprise transportation and expands the use range of powder materials. Therefore, now that briquette machine is more and more popular with customers, what are the criteria for selecting briquette machine? Now I will briefly introduce you:

1.The transmission part of the briquette machine

Briquette machine mainly works and runs by pressure, so when buying a briquette machine, you must carefully observe the motor and reducer. The motor shall ensure that the copper core is the copper core that can achieve the required power.

2. Reducer of briquette machine

The housing and speed ratio of the reducer are very important. After purchasing the Briquette machine, you can basically test it by yourself. At this time, you must consider what kind of strength the adhesive needs to achieve, how to release the product, and how to reduce the rate of product damage. With these issues in mind, you can safely produce and there are almost no problems during the operation of the equipment.

3.Press roller of briquette machine

This is also a mistake prone question. The material requirement of the pressure roller is Mn13 or more, but the company's materials are not up to the Mn13 standard, and many of them are replaced by cast steel materials. When the user uses it for a period of time, it is easy to cause wear and tear, wasting manpower and financial resources. Therefore, the briquette machine must be inquired about the material of the pressure roller of the manufacturer, and testing can be carried out if necessary.

4.Site inspection

On-site testing, on-site visit is very important, which can greatly help us to screen the quality of the ball press equipment.

Fote has been in existence for more than 35 years since its establishment. All of the products have passed the authentication of ISO 9001, CE and GOST. Now FTM®briquette machine has been widely used in large and medium-sized enterprises all over the world. It saves a lot of resource consumption and economic cost for the enterprise and we have thousands of users throughout more than 160 countries in the world. Welcome to consult with.