NEWS

Matters Needing Attention of Ore Powder Briquette Machine

By: Fote MachineryJune 12th,2020

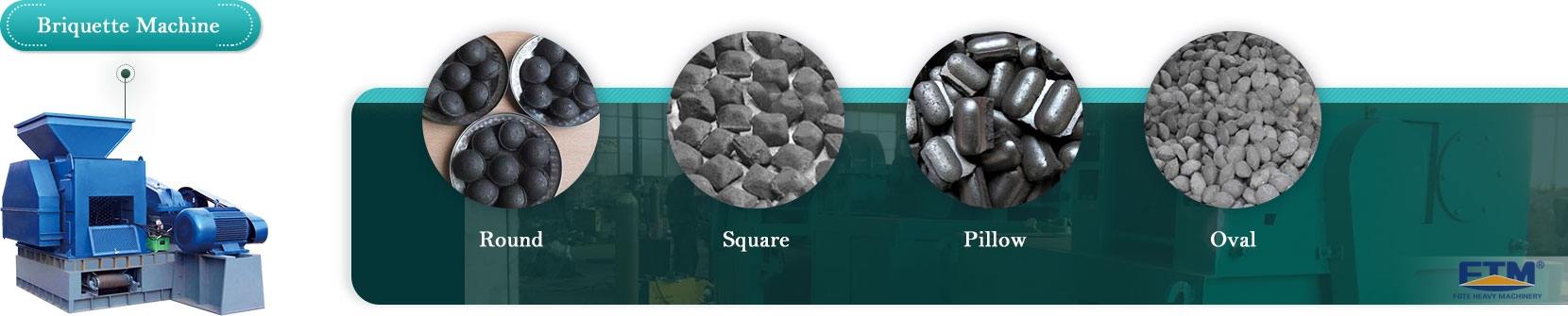

The ore powder briquette machine is widely used. It can press various mineral powder, metal powder, dust removal ash, sludge, steel slag, iron concentrate powder, aluminum ash powder, silicon manganese ore powder and other materials. And the common shapes include: round, square, pillow, oval. Due to the forced extrusion of the roll, the product has three characteristics of high density, high strength and high hardness. In recent years, because of its high quality and wide range of materials, the ore powder briquette machine has a good development. Therefore, there are some matters to be noted when using it.

1. Main engine

Before starting the machine, check whether all parts of the electric appliance are normal, and check whether the die holes of the two rollers are aligned. The working roll spacing shall be kept between 0.4-0.7mm. If it is too large or too small, the passive roll, the bearing and wire drawn can be adjusted. After starting to produce the finished product, check whether the working on the double roll. If there is any error, remove the big gear cover and loosen the outer ring screw of gear for adjustment

2. Blender

In production, if the clutch slips, the fixed wire on the three-jaw frame can be loosened for adjustment. According to the output, the angle of mixing blade on the two shafts can be adjusted. If it is necessary to add the supplementary material (bonding, waterproof), it can be added in the blender.

3. Conveyor

During normal operation, the belt should not be deviated. If the belt is deviated, the front and back roller bearing jacking wire could be adjusted.

4. Feeder

First, start the machine and adjust the tightness of the belt, the belt must not be deviated, and then adjust the size of the gate according to the production capacity of the molding machine to determine the amount of feed.

5. Ore powder briquette machine should pay attention to the following aspects:

5.1 Iron, stone and other similar hard objects shall not be allowed to enter the equipment during the use of the ore powder briquette machine to prevent dangerous events.

5.2 It is strictly prohibited to overload the ore powder briquette machine to prevent irreversible damage to the equipment.

5.3 Continuously observe whether the reducer, bearing seat and rotating shaft are short of oil.

5.4 The lubricating parts of the reduction gear should not run short of oil, otherwise it is easy to have faults.

FTM®Briquette Machine has been in existence for more than 30 years since its establishment. It has three production bases in China and its products are sold to more than 160 countries around the world, welcome to consult with.